Mon. To Sat. 8:30-17:30

info@hanzo.cn

The working principle of a portable plasma cutter is to use the high-temperature plasma arc generated by high-frequency discharge as a "blade" to locally melt the metal to be cut. At the same time, the high-pressure airflow is used to blow the molten metal to the bottom of the cutting surface to form a cutting seam.

Firstly, the equipment converts alternating current into direct current through processes such as voltage transformation and rectification. Then, the direct current reaches the electrode inside the cutting torch, generating an arc between the electrode and the nozzle (anode). Under the action of the arc, the working gas (such as compressed air) passing through the cutting torch is ionized to form plasma.

When the cutting torch approaches the metal workpiece, a circuit is formed between the plasma arc and the metal workpiece. The energy of the high-temperature plasma arc causes the metal workpiece to melt and evaporate rapidly at the contact point, and the high-pressure airflow blows away the molten metal, thereby achieving the cutting of the metal.

Portable plasma cutters have gradually become a trend in the metalworking industry in recent years, mainly due to their advantages in multiple areas.

First, the portability of these devices allows users to perform cutting operations at different job sites without the need for a fixed workbench or complex setups. This is extremely convenient for workers who need to move frequently or work on-site.

Secondly, portable plasma cutters typically have lower costs and maintenance expenses, making it easier for small and medium-sized enterprises and individual users to access this technology. With advancements in technology, the performance of these devices has also improved continuously, enabling them to handle various conductive materials such as aluminum, stainless steel, and low-carbon steel.

Additionally, portable plasma cutters are known for their high efficiency and precision. Compared to traditional flame cutting methods, they can complete cutting tasks at a faster speed while providing better cut quality. This makes them the preferred tool in many applications.

Advantages:

Portability: The compact design makes the equipment easy to transport and usable at different locations.

Cost-effectiveness: Compared to larger machines, initial investment and maintenance costs are lower.

High efficiency: Capable of quickly completing cutting tasks, thus improving productivity.

Wide applicability: Can be used on various conductive materials including aluminum, stainless steel, and low-carbon steel.

Ease of operation: Most portable devices are user-friendly and easy to learn.

Disadvantages:

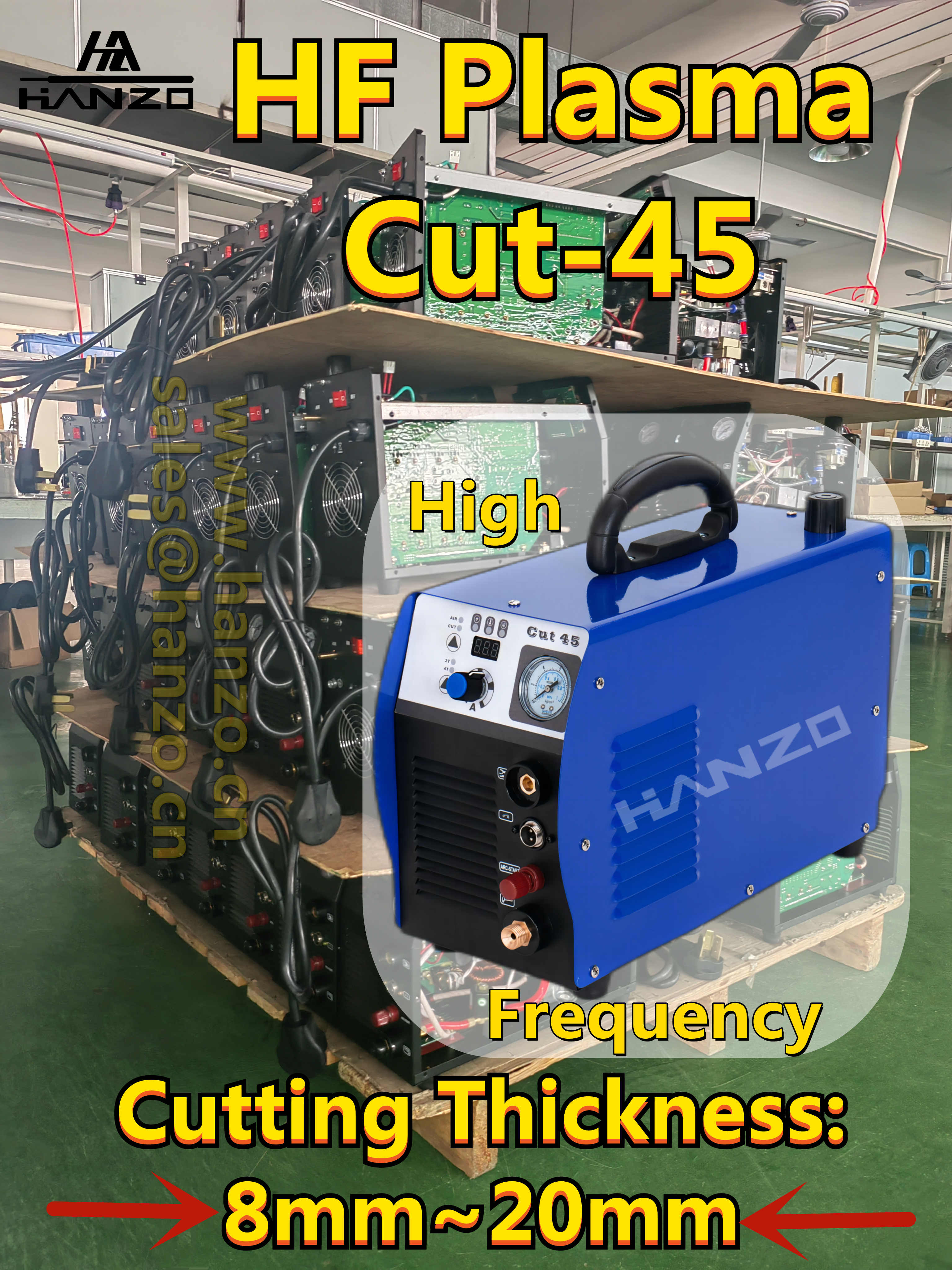

Power limitations: Due to their smaller size, some models may not be able to handle very thick metal materials.

Durability issues: Compared to industrial-grade large machines, portable devices may lack durability.

Noise and fumes: Operation may produce noise and fumes that can impact the environment.

Safety risks: Since operators often work on-site, extra attention is needed for safety precautions to avoid accidents.

In summary, portable plasma cutters have become a trend due to their flexibility, cost-effectiveness, and high efficiency;

however, they also come with certain limitations and potential risks.

|

|

|

+86-13923298312 info@hanzo.cn New Lighting Source Industry Zone B3, Luocun Town, Nanhai, Foshan, Guangdong, China.

|